Modern construction needs modern materials.

Design innovation combined with increasing pressure from Building Regulations means that materials must save time and money on site and offer technically superior solutions.

Fermacell is one such material. A high performance multi-purpose building board that when installed combines the properties of solid blockwork with the speed and flexibility of conventional drywall techniques, letting designers use radical solutions in internal space planning.

COMPOSITION

Fermacell is produced using ordinary materials in an extraordinary way. Recycled gypsum, recycled cellulose fibres from post consumer waste paper and recycled water are combined to form a homogenous mass, which is then formed into a dense sheet material. After drying, the large format

boards are cut to size.

The manufacturing technique is not only unique because of the material it produces, but also due to the fact that the process itself is fully recycling – all by-products are fed back into the system, ensuring no waste is produced. Both the product and the process have been awarded the coveted Rosenheim Institute of Construction Biology and Ecology certificate.

Fermacell boards are third party accredited by BBA, ETA and the ECO Instute.

GENERAL PROPERTIES AND APPLICATIONS

There are a vast array of construction systems and techniques to consider when specifying internal finishes.

For partitions, this is most apparent when the properties required of the finished wall call for more than one type of building board to be used in the construction. Hotel bathrooms, for example, often require Moisture Resistance with Acoustic Insulation and Fire Protection.

Hospitals will add Impact Resistance and flexibility in accepting wall mounted fittings to this. These criteria almost always demand compromise solutions involving specialist board selection and composite layers, often with costly and time consuming consequences. This in turn creates the potential for confusion, both at detailed drawing stage and on site. Additionally, multiple layering inevitably means thicker walls.

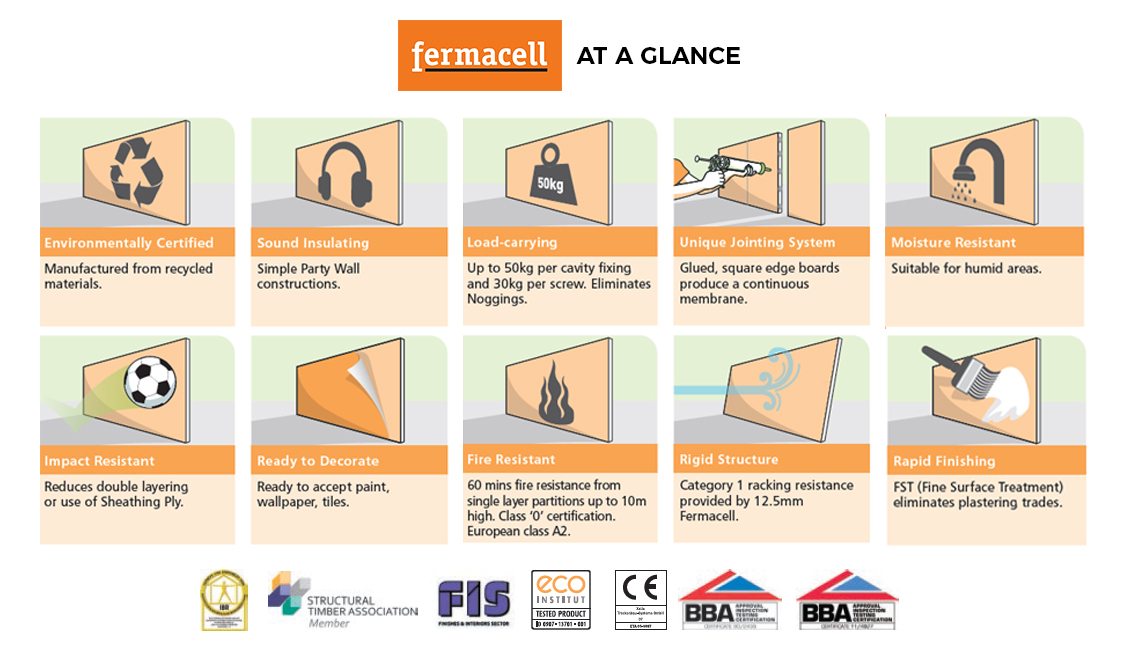

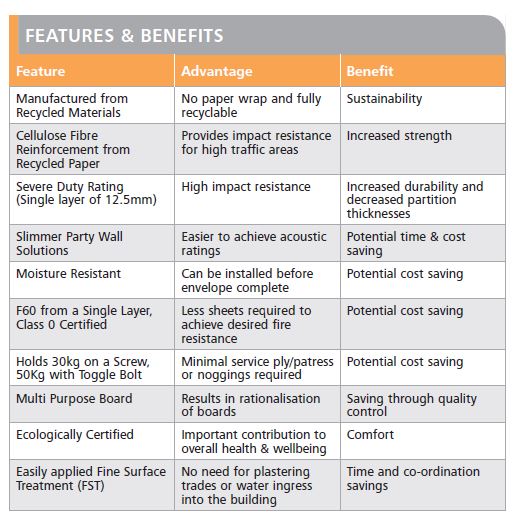

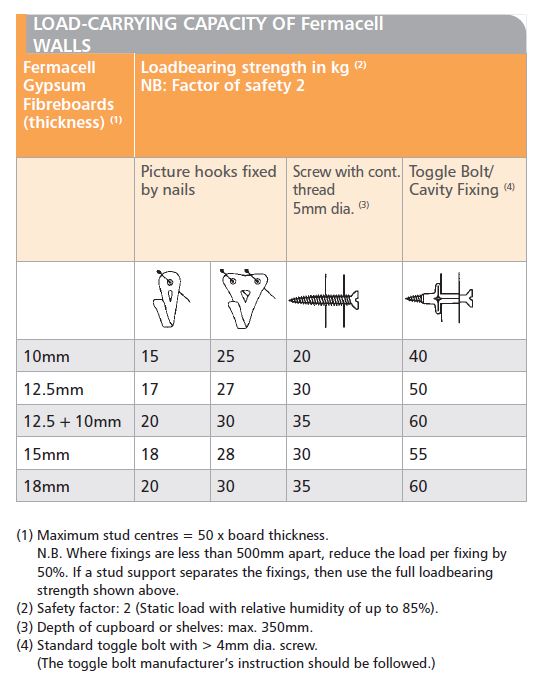

Fermacell offers a unique, single point solution to these problems, combining high levels of Fire Resistance, Acoustic Insulation and Impact Strength with exceptional Screw Holding ability and inherent Moisture Resistance.

From Commercial Projects through to DIY, Fermacell can reap rewards. Fermacell requires minimal additional work prior to painting and decorating. Wallpapers and tiles can be applied direct to the board, and plaster smooth finishes, which are ready to paint in about 45 minutes can be achieved by non-skilled trades using our FST (Fine Surface Treatment) system.

The end result is a finished partition that combines the properties associated with solid masonry with the flexibility of drywall, in a construction that is often thinner, quicker and cheaper to install than both. Using a multi-purpose board that eliminates unnecessary wet trades makes practical, technical and commercial sense.